This ZWC de-energized tap-changer is suitable for oil-immersed power transformers and special transformers, such as furnace or rectifier transformer with a rated frequency of 50 or 60 Hz, a maximum equipment voltage of 145kV and maximum rated current of 1000A. Tap changing takes place when the transformer is de-energized, so as to change the transformer ratio and stabilize the output voltage.

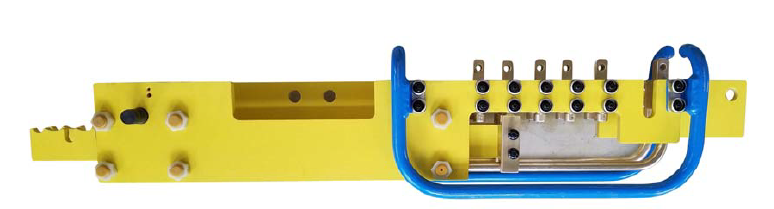

ZWC tap-changer

Drive mechanism

ZWC is of a split structure and consists of two parts: the body and the drive mechanism. The transformer manufacturer is responsible for connecting these two. It is of linear type and equipped with two insulating support plates as a frame. It is used in power transformers and large-scale distribution transformers. It is installed in the space between the windings and the tank wall. It benefits from a compact size and reduced tapping lead. The tap changer operation is controlled by a Geneva wheel to ensure accurate positioning of the moving and fixed contacts. The appropriate connection between the tap changer contacts is done through a classic clamping-type floating point method to meet the the current carrying capacity.

1 | Tap-changer Model | ZWCI 500 | ZWCI 1000 |

2 | Phases | Single phase |

3 | Rated frequency(Hz) | 50/60 |

4 | Rated through current(A) | 500 | 1000 |

5 | Short-circuit current test(kA) | Thermal(3s) | 8 | 15 |

Dynamic (Peak) | 12.5 | 25 |

6 | Insulation to ground | Voltage(kV) | 138 | 138 |

The highest voltage for equipment(kV) | 145 | 145 |

Rated separate source AC withstand voltage(1min)(kV) | To ground | 275 | 275 |

Between contact | 50 with 50mm spacing | 50 with 50mm spacing |

80 with 80mm spacing | 80 with 80mm spacing |

Between max. & min. taps of the same phase | 100 | 100 |

Rated lightning impulse withstand voltage(1.2/50μs)(kV) | To ground | 650 | 650 |

Between contact | 140 with 50mm spacing | 140 with 50mm spacing |

225 with 80mm spacing | 225 with 80mm spacing |

Between max. & min. taps of the same phase | 250 | 250 |

7 | Drying temperature(℃) | Vacuum drying 110℃, Vapor phase drying 125℃ |

8 | Connection mode | Linear |

9 | Operating method | Side manual operation |

10 | Max. operating positions | 5 |

11 | Contact resistance between fixed and moving contacts | ≤350μΩ |

12 | Partial discharge(pC) | ≤50 |

13 | Leakage test | No leakage under 6×104 Pa for 24h |

14 | Mechanical life | More than 10,000 operations |

15 | Temperature rise of contact at 120% of rated | Below 15K (in oil) |