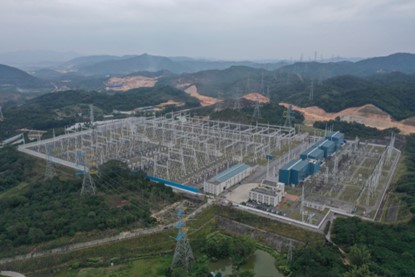

On November 27, China's first independently developed converter transformer with a domestic on-load tap-changer was successfully put into operation at the Xiluodu DC Project from West Converter Station, a key project of West-East Power Transmission, located in Conghua, Guangzhou.

'The on-load tap-changer of the converter transformer has completed a technological breakthrough from scratch and achieved full localization of group components and other industry chains, marking a breakthrough in this key core technology constraint of high-end power equipment in China.' said Feng Thrush, deputy general manager of the Biotechnology Department of the South China Power Grid UHV Company.

China's east and west across thousands of kilometers, west-east power transmission needs to use long-distance, high-capacity, high-voltage DC project for power transmission, project transmission end and receiving end site are to use more than 300 tons of converter transformer this hub equipment. The on-load tap-changer of the converter transformer is like an automatic 'gearbox' of a car, the voltage is adjusted higher and lower, the load is adjusted more and less, the current is adjusted larger and smaller through it to adjust.

The on-load tap-changer is a highly complex and sophisticated piece of equipment. According to Deng Jun, a senior technical expert of the Southern Power Grid UHV Company, the on-load tap-changer of the converter transformer has more than 1,000 parts and components, and the switching times are very frequent, up to 6,000 times a year, a switch includes 9 processes, each action involves more than 400 parts of the precise cooperation, and the timing of each process with milliseconds, the action process involves electric, thermal, force multi-field coupling role.

Due to the extremely high reliability requirements and manufacturing difficulties, this technology has been in the hands of a few foreign manufacturers, and equipment maintenance is also limited. Once a failure occurs, only imported products of the same type can be replaced, and the order cycle takes 3 to 4 months, which brings challenges to the safety of power operation.

Liu Xiangqiang, deputy general manager of Southern Power Grid UHV Company, told reporters that the research team jointly formed by Southern Power Grid UHV Company and upstream and downstream enterprises in the industry chain has overcome the core technical problems such as vacuum switching tubes after more than 2 years of efforts, and successfully developed a large-capacity converter on-load tap-changer with rated capacity of 6000kVA, maximum voltage of 6000V and maximum rated current of 1300A, realizing The whole chain of 'raw materials-group components-complete machine' has been manufactured domestically.

The successful commissioning of this product will not only help upgrade China's high-end electrical equipment industry chain, but also save costs for engineering construction. According to Liu Xianggun, only from the equipment cost estimates, domestic converter transformer on-load tap-changer can make a new ultra-high voltage DC transmission project to save costs of nearly 40 million RMB.